Microscopy is inextricably linked to Delft thanks to Antonie van Leeuwenhoek, who was the first to discover cells and microbiological structures with his self-built microscopes in the 17th century. A tradition microscope builder Delmic has been continuing since 2010 with innovative microscope technology. We spoke with Jacob Hoogenboom of TU Delft who was involved in this innovative company early on and still works closely together with the company.

Hoogenboom, Associate Professor at the Faculty of Applied Sciences (TNW), explains that the Netherlands has a strong reputation in microscopy, but that until ten years ago this rarely translated into new business or commercial activities. “Thermo Fisher is, for example, a world leader in electron microscopy and traditionally a company with strong ties with Delft, located in Eindhoven. But such a large company often sees no commercial profit in innovative but small-scale products.” In 2010, the idea arose to set up Delmic and to serve niche audiences within microscopy. The first product is a combination of an electron microscope and a fluorescence microscope. Hoogenboom explains the difference: “an electron microscope has a much higher resolution than an ordinary light microscope. But a fluorescent light microscope is ideal for biological and medical research, because you are able to use fluorescent dyes that you can stick to specific proteins and then light up with a specific form of lighting. With the combination of the two you can look at tissues at particularly high resolution and at the same time make proteins or hormones visible. ”

Low chances of commercial success

The market for these types of microscopes is small and consists mainly of universities and teaching hospitals. TU Delft was not immediately convinced that there would be a viable market, Hoogenboom explains. “Because TU Delft was initially also sceptical, we founded Delmic ourselves. After taking over a first patent application, support from the NWO followed, and we started to expand the company steadily. “Hoogenboom says it was a different world back then compared to the entrepreneurial climate around TU Delft now: ” The Valorisation Centre (now called the Innovation & Impact Centre) had just started then. The procedures surrounding IP and stimulating entrepreneurship were still in their early days. Exactly how a university can stimulate business activity can be a complex issue. As a university you do not want to get in the way, but you also do not want to give up all your “recipes” just like that. Now all that is better-managed. ”

“We’re going to do it”

Delmic started within the faculty walls of Applied Sciences, but it soon became time for their own office space. Those were found at incubator YES! Delft. Hoogenboom: “It was ideal to get an office there for a while. You feel the hustle and bustle and there really is an atmosphere of “we’re going to do it”. Entrepreneurship is in the air in that building. And there is an incredible amount of knowledge and advisory power there that is of great use to you as a starting company.” The background of other entrepreneurs at YES! Delft came as a bit of a surprise to Hoogenboom: “I expected a lot of research-driven companies. But in practice it turned out that there were also an great amount of students walking around who started entrepreneurship based on their own ideas – really very nice to see.”

Symbiosis between start-up and university

Delmic has since grown into a SME but is still firmly rooted in the Delft ecosystem of innovative companies and now holds office in a stately building right next to TU Delft Campus. Delft Enterprises is involved as a shareholder and Delft students come and go for internships and research at the company. These are not just Applied Sciences students, Hoogenboom explains: “Of course there are students in Nanobiology (a study within Applied Sciences), but mechanical engineering students also know how to find their way to Delmic. Apart from the many alumni and former PhD students who now work there. ”

‘It really works both ways’

From the outset, the two parties benefited from each other, says Hoogenboom. “When Delmic started, they were able to use TU Delft facilities that a normal start-up normally does not have access to. Delmic in turn has improved the prototype in our lab so much that working with it is much easier and we do so much more with it. Lines of communication are short and we as a university certainly benefit from this. It really works both ways. Our research yields new insights for a business developer like Delmic. If we have questions or new requirements in terms of functionality, we can easily switch with Delmic’s software engineers. There is really a big win-win there.

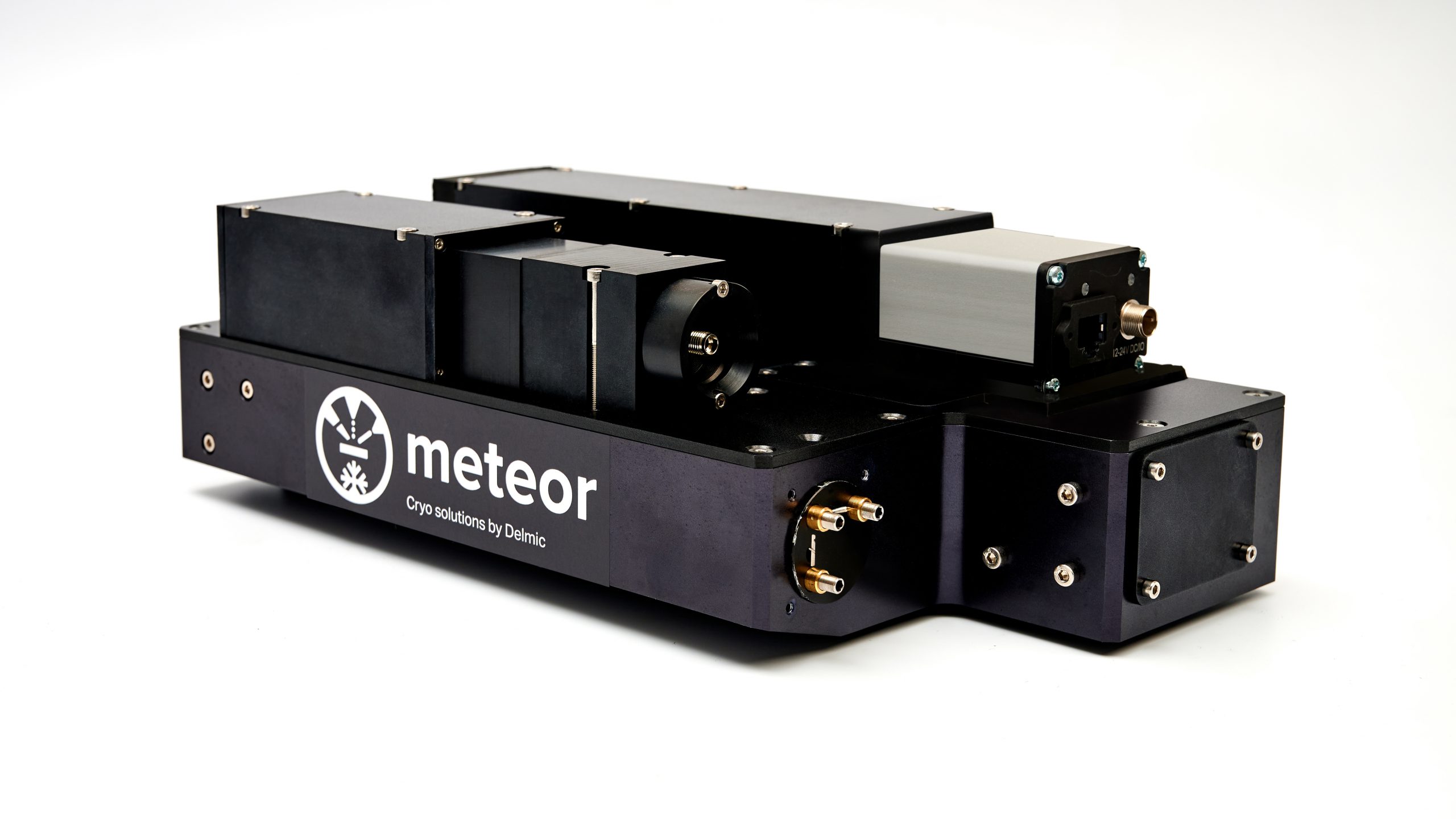

These days Delmic works together with several (technical) universities. “Continually developing new technology is so expensive that neither the university nor Delmic can afford it. Hoogenboom: “It is simply too risky. But it can be done by collaborating with other academic partners. An example is cryogenic microscopy – cryo-EM. In this type of microscopy, biological samples are cooled down to extremely low temperatures, so that molecules are shown in a particularly detailed image. New, cutting-edge technology, but also incredibly expensive to develop. “By joining forces with universities from Australia, the United States and Germany, among others, it has become feasible for Delmic to further develop this type of microscope. “Here, Delmic has been able to develop a revolutionary new product through close cooperation with TU Delft and these other universities. One of these first microscopes will soon be at TU Delft.”

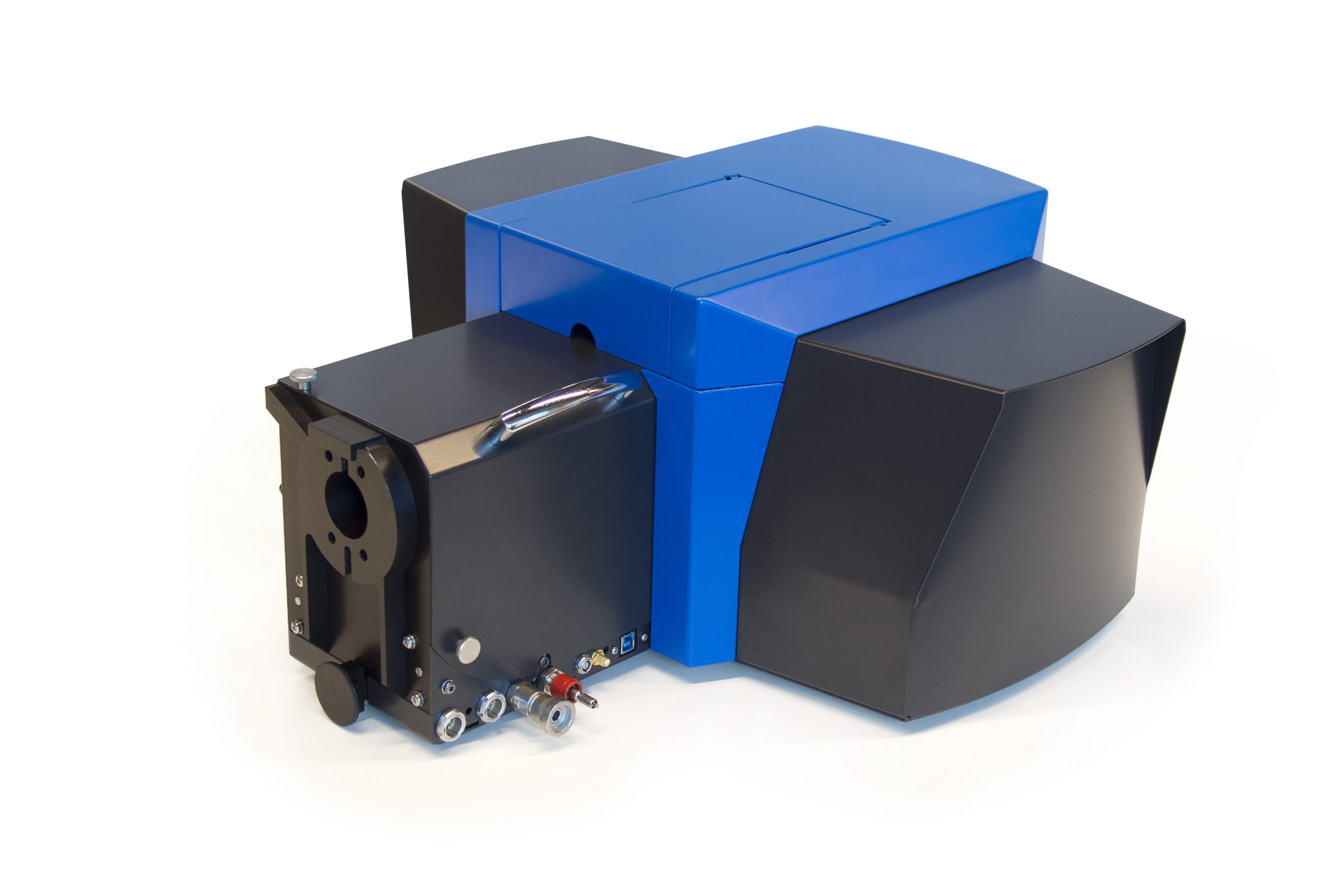

Future plans: cryogenic microscopy and FAST-EM

For the near future, Delmic is investing in two new systems: cryogenic microscopy and FAST-EM: a new method for scanning large quantities of complex tissues. This is interesting for medical specialists such as pathologists, who have to view large amounts of data. Manual work for operators behind the microscope can be automated and shared online with specialists. Both products have something new to offer a clearly defined target group of users. Hoogenboom: “That was handled completely different in the past. Back then a technician would come up with something very clever, get back to end-users who then had to figure out if they could actually work with it. Readying preparations for microscopy is complex work. Tools have to fit, systems have to be able to ‘talk’ to each other and be suitable for those very specific preparations. By working together with all these different parties, we can pay more attention to meeting each others needs than before. By working within TU Delft with products from Delmic and with preparations and research questions from biologists and physicians, we also get ideas about new features for further development. That is very valuable for all parties involved. ”